-

브루노 나시멘토고품질의 저렴한 제품을 제공해 주셔서 감사합니다.

브루노 나시멘토고품질의 저렴한 제품을 제공해 주셔서 감사합니다. -

에흐산 살마리신속한 답변과 전문적인 태도는 우리의 협력을 더 원활하게 만듭니다!

에흐산 살마리신속한 답변과 전문적인 태도는 우리의 협력을 더 원활하게 만듭니다!

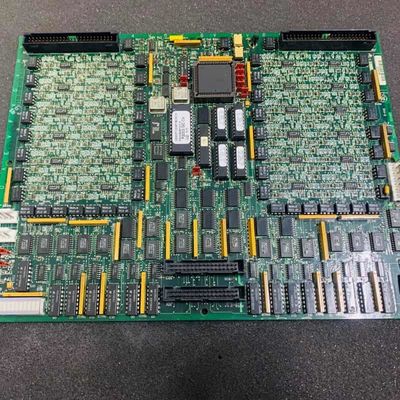

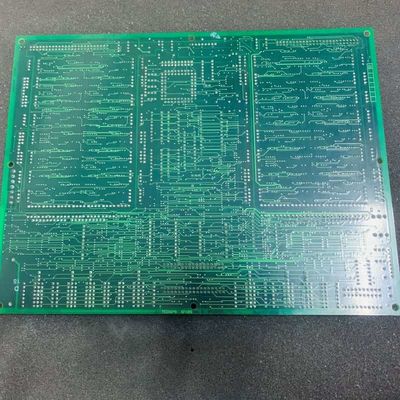

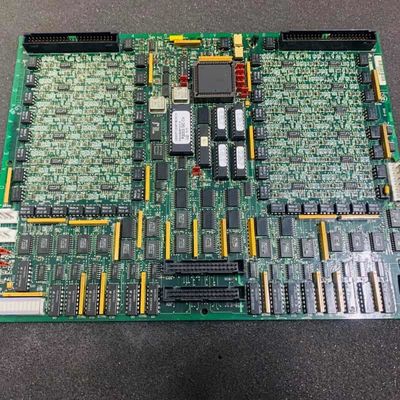

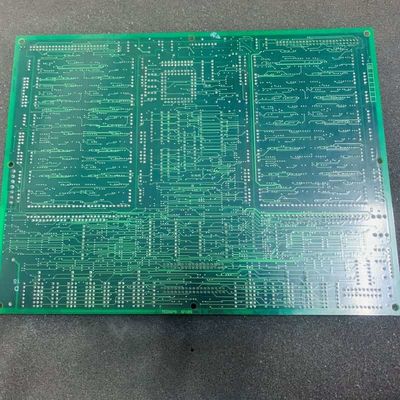

GE DS200TCDAH1BHD 디지털 I/O 보드 전면 아날로그 신호 처리 2kg 무게와 1년 보증

| 이름 | GE DS200TCDAH1BHD DS200TCDAH1B 디지털 I/O 보드 | 제품 ID | DS200TCDAH1BHD |

|---|---|---|---|

| 시리즈 | 마크 v | 기능 | 이산 출력 팩 |

| 제품 순 깊이/길이 | 330mm | 제품 순 높이 | 200mm |

| 제품 순 폭 | 100mm | 제품 순 중량 | 2kg |

| 보증 | 1 세 | ||

| 강조하다 | 포괄적 인 아날로그 신호 처리 디지털 I / O 보드,2kg 무게 I/O 보드,1년 보증 디스크리트 출력 팩 |

||

GE DS200TCDAH1BHD DS200TCDAH1B 디지털 I/O 보드

제품 세부 정보:

GEDS200TCDAH1B는 GE의 Mark V 터빈 제어 시스템을 위해 특별히 설계된 디지털 I/O 보드입니다. 이 시스템은 풍력, 가스 및 증기 터빈 자동 구동 장치를 관리하는 데 사용되는 레거시 시리즈이며, 특허받은 Speedtronic 제어 기술을 통합한 마지막 GE Mark 라인 중 하나입니다.

기능적으로는 다양한 아날로그 신호를 처리합니다. JBB/JAA를 통한 4-20mA 입력/출력(전압 판독을 위해 부하 저항을 통해 전류 강하), JCC/JDD를 통한 RTD 입력(여기 공급 및 온도 의존적 저항 측정), JAR/S/T를 통한 열전대 입력(TBQA의 냉접점 보상을 사용하여 실제 온도 계산), JBB를 통한 터빈 샤프트 전압/전류 신호. 모든 조정된 신호는 3PL 커넥터를 통해 I/O 엔진으로 전송되며, 소프트웨어 구성 열전대 유형, HMI의 I/O 구성 편집기를 통해 관리되는 RTD 설정이 있습니다.

주요 특징:

포괄적인 아날로그 신호 처리:4-20mA 신호, RTD, 열전대 및 샤프트 전압/전류의 중앙 허브 역할을 합니다. 데이터 크기 조정, 조정 및 I/O 엔진으로 전송하여 터빈 성능 모니터링 및 제어에 중요합니다. 연료 흐름 또는 냉각 시스템 조정과 같은 실시간 조정을 안내하는 정확한 데이터를 보장하기 위해 노이즈를 제거하여 원시 신호를 개선합니다.

탈착식 및 ESD 민감 PROM:탈착식 PROM 모듈은 펌웨어를 저장합니다. 손목 스트랩과 같은 ESD 보호 기능을 갖춘 모듈로 교체하면 교체 보드가 동일한 지침을 유지하여 원래 보드의 기능을 일치시킵니다. 이렇게 하면 펌웨어를 재구성할 필요가 없어 유지 관리 시간을 단축하고 교체 후 일관된 신호 처리 로직을 보장합니다.

구성 가능한 하드웨어 및 소프트웨어:세 개의 점퍼(J1/JP2/JP3)는 하드웨어 조정을 처리하는 반면, 소프트웨어 설정은 열전대/RTD 유형 및 신호 매개변수를 사용자 정의하여 다양한 터빈 요구 사항에 적응합니다. J1은 RS232 포트를 관리하고, JP2는 테스트를 지원하며, 소프트웨어는 터빈별 센서 설정에 원활하게 맞게 조정됩니다.

전용 구성 요소 인터페이싱:9개의 커넥터(8개 기능, 1개 잔존)는 주요 Mark V 보드(TCPS, CTBA, TBCA, TBQA)에 연결되어 전원, 데이터 및 진단 신호 전송을 원활하게 수행하여 상호 간섭 위험을 제거합니다. 각 커넥터의 특정 역할은 신호가 간섭 없이 대상에 도달하도록 보장하여 시스템 안정성을 높입니다.

테스트 중심 설계:점퍼(JP2/JP3) 및 특수 커넥터는 공장 테스트 및 유지 관리를 지원하여 문제 해결을 단순화하는 동시에 규범적 작동 신뢰성을 보장합니다. JP2는 안전한 테스트를 위해 발진기를 비활성화하고, 커넥터를 통해 기술자가 문제 진단을 위해 신호에 쉽게 액세스할 수 있습니다.

![]()

![]()

| DS200DTBBG1ABB | DS200TCCAF1BDF |

| DS200SDCIG2AFB | IS200ISBBG1AAB |

| DS200SDCIG2AHB | IS200CABPG1BAA |

| DS200BDAAG1AAA | IS200DSFCG1AEB |

| DS200SIOBH1ABA | IS200DRLYH1BBB |